GHL型高速混合制粒机

| GHL型高速混合制粒机 | ||

|

用途

工作原理

特点 |

||

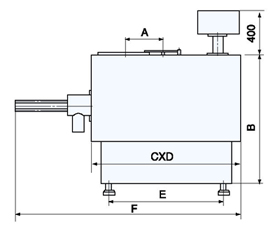

外形尺寸

|

|

|

技术参数

|

项目 |

规格 |

|||||||||

|

名称 |

单位 |

10 |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

800 |

|

容积 |

L |

10 |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

800 |

|

产量 |

Kg/批 |

3 |

15 |

50 |

80 |

100 |

130 |

180 |

280 |

350 |

|

混合速度 |

r.p.m |

300/600 |

260/400 |

240/360 |

180/270 |

180/270 |

140/220 |

106/155 |

80/120 |

80/120 |

|

混合功率 |

kw |

1.5/2.2 |

4/5.5 |

6.5/8 |

9/11 |

9/11 |

13/16 |

18.5/22 |

22/30 |

26/34 |

|

切割速度 |

r.p.m |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

1500/ 3000 |

|

切割功率 |

kw |

0.85/1.1 |

1.3/1.8 |

2.4/3 |

4.5/5.5 |

4.5/5.5 |

4.5/5.5 |

6.5/8 |

9/11 |

9/11 |

Detailed Description

The company mainly produces a series of deck and cabin machinery products: specifically shell-and-tube/plate heat exchangers, spark extinguishing silencers, hot well units, pressure water tank units, hot water tank units, water supply modules, air bottles, oil/water filters , Wire rope electric hoist, engine room crane, sea water desalination device, and constant pressure frequency conversion water supply unit, mud tank, radiator, heater, hose barge, etc., are widely used in various marine engineering, supporting ships, oil fields, chemical industry, In power and other fields, it has successively provided supporting products for major domestic shipyards such as Hudong Zhonghua, Jiangnan Shipbuilding, Shanghai Shipyard, Guangzhou Shipyard International, Dalian Shipbuilding Industry, Bohai Shipbuilding Industry, Qingdao Beihai Heavy Industry, COSCO Kawasaki and other major domestic shipyards.

Marketing Department:

Office: 86-513-85928789

Fax: 86-513-85928785 85928778

Email: service@ntcj.com

Add: No. 118, Xinkai Road, Economic and Technological Development Zone, Nantong City, Jiangsu Province

Marketing Department:86-513-68012701 85928780

Purchasing Department: 86-80565366

Office:86-513-85928789

E-mail:service@ntcj.com

Add:No. 118, Xinkai Road, Economic and Technological Development Zone, Nantong City, Jiangsu Province

© 2021 Nantong CSEMC Machinery Manufacture Co., Ltd.

English

English 中文版

中文版

86-513-68012701

86-513-68012701  service@ntcj.com

service@ntcj.com  Feedback

Feedback